China is the world’s largest producer and exporter of clothing. Apparently, it is also the country with the largest number of garment factories. All garment products are completely in different levels of the quality due to the complexity of the process in the garment industry, the variability of the upstream and downstream supply chains, as well as the different management levels of factories leaders themselves. As the professional hunting clothing designer and manufacturer, which supply both OEM and ODM service. BOWINS Garment is always work harder and try its best to improve production management level, so we can keep up with the industry leaders and keep our products competitive for its quality, price and delivery time.

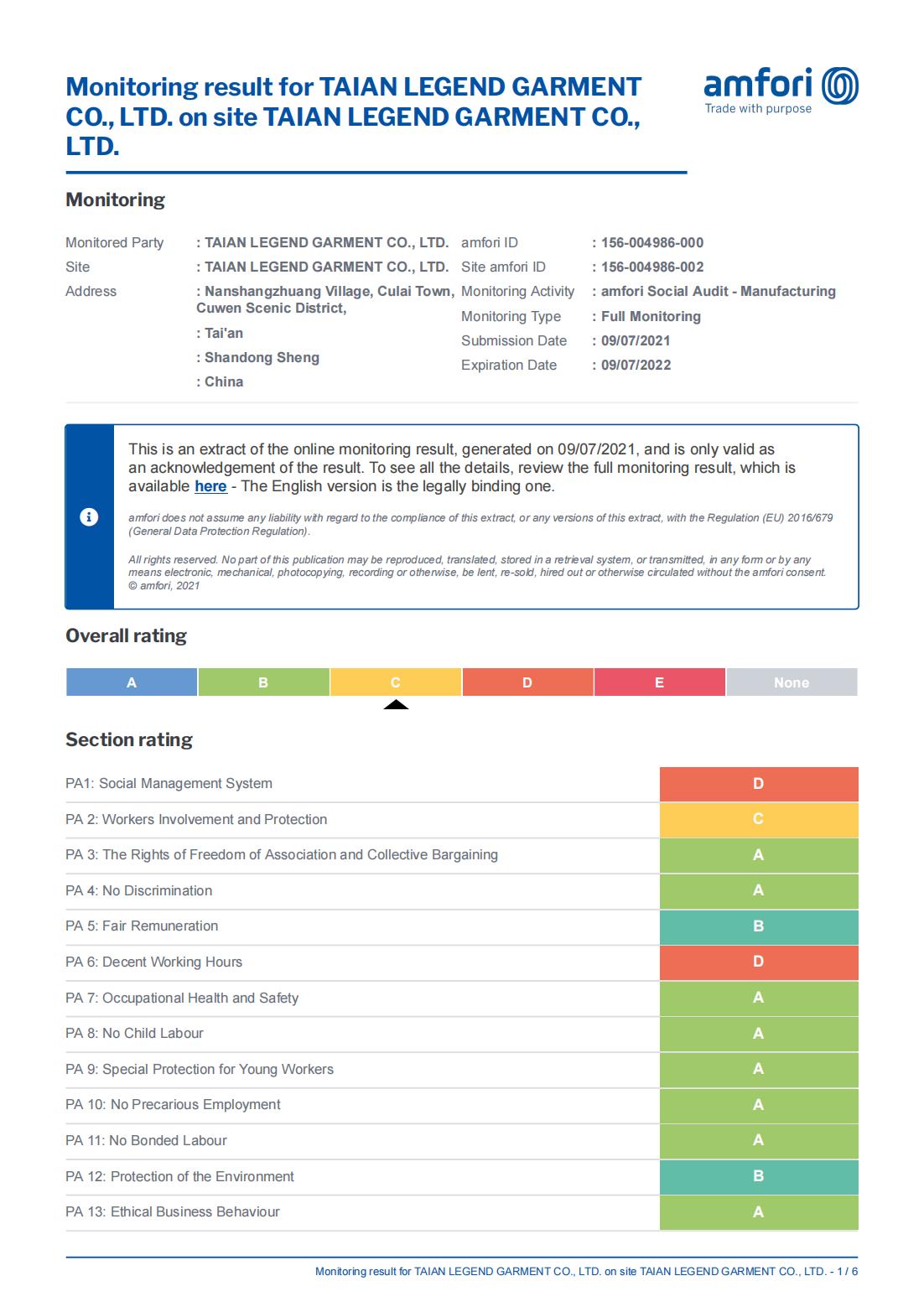

The majority of high quality customers will come to this problem, how to quickly choose a higher level of suppliers to achieve a long-term stable cooperative relationship? The qualification to have one or more internationally accepted factory inspection tests becomes a significant symbol for all factories. Then in this article, I will share some of the BSCI standards showing out at Bowins hunting wear factory – Taian Legend Co., Ltd.

BSCI, the “Corporate Social Compliance Initiative”, is aiming to manage a set of unified procedures to monitor and promote the social responsibility performance of companies that produce related products through continuous improvement of development policies.

The members of the Business Compliance Organization (BSCI) include retailers, brand companies and traders. Most of the textiles business members are from 10 countries in Europe and Canada, and 18 members are from the Netherlands, such as HEMA, Bijenkorf, V&D, Claudia Sträter, M&S, Hunkemöller, WE, Wehkamp, etc. In other words, BSCI originated in the textile industry, extended to various categories of clothing industry, and further responded to household and food.

The purpose of BSCI certification is to sustainably improve the global supply chain. The implementation of BSCI certification not only saves costs and time for manufacturers to avoid repeated audits, but also brings economic benefits to retail companies and suppliers. At present, only independent audit companies that have passed the SAI qualification level appraisal and selected by BSCI will be entrusted to implement BSCI social responsibility audits, which not only guarantees the best audit quality, but also avoids expensive and corrupt audits. There are more than 180 BSCI members and most of the wholesalers and purchasers in Europe are BSCI members. BSCI members will allow their contracted suppliers from various countries to accept BSCI factory inspections to improve the human rights status of the factories.

Hunting wear, the product itself is a kind of functional clothing to protect personal safety in various hunting environments. Such as hunting jackets with removable hi-vi orange vests, suede jackets with orange armbands, hunting gloves, hunting guard and special multi-functional multi-pocket orange hunting vests with back straps. Wear a jacket and vest with safety strap holes, there are also non-license orange camouflage deer hunting suits, a seams taping raincoat with high water pressure and moisture permeability for rainy weather, and blaze orange vest for dogs.The origin of hunting gear brands also considers the humanitarian factors. In this case, hunting wear factory should become even more representative factories with BSCI.

Bowins has wholly-owned factory- Taian Legend Factory, the latest BSCI certification number 156-004986-002, and the review agency is China SGS.

The following text introduces a series of management steps carried out by Legend under the BSCI standard.

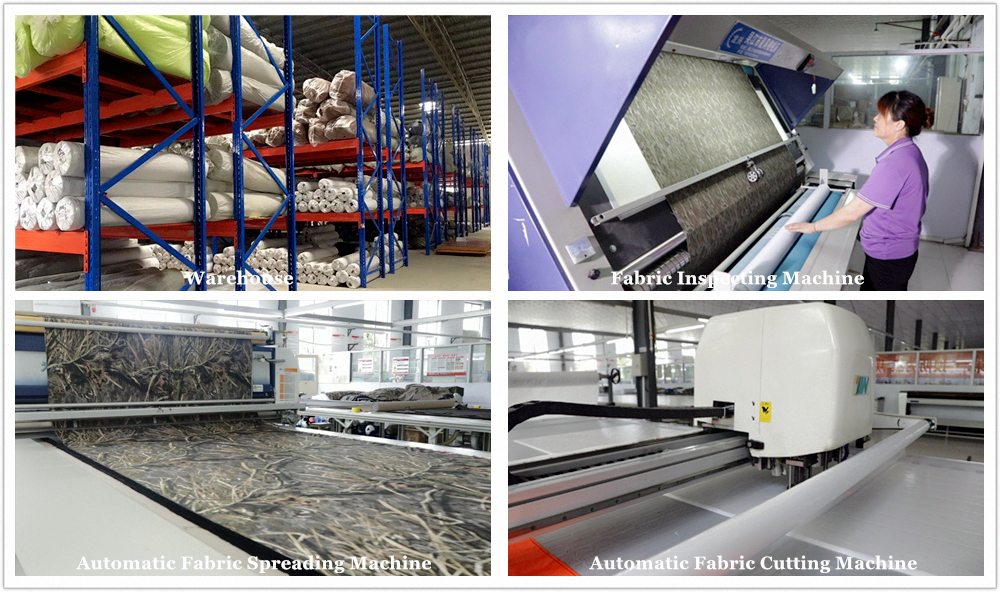

TAIAN LEGEND GARMENT CO., LTD. was founded on 17 Sep., 2010 and located at Nanshangzhuang Village, Culai Town, Cuwen Scenic District, Taian City, Shandong Province.Main process was listed as below: cutting/sewing/Ironing/inspection/packing.

Auditor arrived the factory about 08:30 AM on Jul 1, 2021. Opening meeting was held at 08:45 AM. Ms. Liu Qingmei (Production supervisor), Ms. Zhou Xin (Admin supervisor) and worker representatives named Wu Yan’an were presented at the meeting. The management showed a positive and cooperative attitude during the audit.

The factory agreed SGS auditors conducted confidential interviews with workers who were chosen freely without any influence by the factory. Interviews with all the 11 employees were conducted in an independent room. The interviewees showed a cooperative attitude and most workers were satisfied with working condition and benefits in the factory.

All the attendees who attended the opening meeting were presented at the closing meeting which was held about 12:00 PM on

Jul 2, 2021. Ms. Zhou Xin and Mr. Wu Yan’an signed the on-site CAP.

Remark:

- There was no agency used by the auditee, which maked the agency labour contract not applicable.

- There was no Documented valid authorisation to make exemptions about working hours.

- The factory rented two 1-storey buildings as production, warehouse and office from the landlord. During the audit, the factory provided lease contracts for review.

Auditing company name: SGS

The name of the auditors: Vicky Ma

APSCA number and status: CSCA 21701735

Audit date: Jul 1-2, 2021

A trade union was founded in the factory, also worker representatives were elected by workers themselves. Workers had monthly meeting for getting the information of workplace-related issues, the factory also provided regular training on workers’ right to them.

The factory established policy on anti-discrimination. The policy defined that the factory would not discriminate workers by gender and ages etc.

And according to interview with workers, workers could use the grievance system through suggestion boxes or telling to worker representatives once workers’ right was infringed.

The factory has formulated working hours policy that all workers worked 5 days per week, 8 hours per day and 40 hours per week, the working hours was from 7:30 to 11:30, 13:30 to 17:30. All workers could have one day off after 6 consecutive working days.

The committee of health and safety including worker representative was set up by the factory Mr Wang, the Factory Director was in charge of the affairs of health and safety. According to on-site observation, the highest risks of health and safety in the factory were fire safety and electrical safety. The first aid box was also available in every workshop. Clean potable water was also provided and all workers could access the potable water freely.

The policy of young worker protection was made by the factory. The factory understood the legal requirement of young workers according to interview with management.

Labor contracts were signed between the factory and all workers, the factory provided a copy of contract to every worker.

The factory established the policy on anti-forced labor. The management staffs understood well of the scope of forced labor.

The latest SGS inspection was completed on August 21, 2020. Legend Factory was approved by BSCI and obtained the A-level of 8 projects. Although there are some shortcomings, I believe there will be a progressive improvement under the guidance of Bowins Garment Co.,LTD and Legend Factory.

We will pay more attention on workers’ monthly overtime hours, social management system, workers involvement and protection, protection of the environment and so on.

Just believe BSCI, believe BOWINS hunting wear, we will always be on the way.

As a professional hunting wear manufacturer with BSCI, we pay special attention to the safety and eco-friendly in the hunting process. Production of a variety of safe hunting suits with recycled fabric for different hunting activity. I believe there is always a product to meet your hunting needs, please feel free to consult and purchase!