With the promotion of the popularity of the hunting clothing market, the application of waterproof adhesive strip technology in hunting clothing is more and more extensive, from the previous single category gradually to the whole category, the stage of serialization. At the same time, the practical operation difficulty of waterproof adhesive strip process and the effective matching with different fabric properties also brings an unprecedented challenge, which is a technical problem throughout the hunting suit industry.

In the traditional waterproof adhesive strip technology, special pressing adhesive strip equipment is used to realize adhesive strip sticking. When the special pressing rubber strip equipment is working, the rolled rubber strip is gradually pulled out and gradually attached to the lining of the fabric driven by the roller, and the hot blow air generated on the pressing rubber strip equipment is used to heat the rubber strip so that it is bonded to the fabric. In the process of adhesive strip attached to the fabric, the alignment and straightness of adhesive strip relative to the joint on the fabric are controlled by the operator. It is more difficult to control the process of radian modeling parts, and it is difficult to evenly maintain the width and width of the seam. This requires higher proficiency of users, that is, higher ability of operators, and accordingly increases the cost of enterprise employment. In addition, the pressing rubber strip equipment requires a very high matching performance between the rubber strip and the fabric. In addition, the speed of pressing has a direct impact on the adhesive fastness of the adhesive strip. The size of the rubber strip slot used by the pressing rubber strip equipment is limited. That is, the size of the rubber strip slot should be based on the actual width of the rubber strip. Different widths of the rubber strip need to be replaced with appropriate rubber strip slots.

Based on the existing high-end pressing rubber strip equipment, according to the actual fabric characteristics and process needs, our company adopts a pressing equipment with strong comprehensive performance, which effectively solves a series of problems such as difficult pressing, difficult operation and low efficiency of rubber strip on different fabrics under the background of production and labor difficulties in today’s industry.

First, hunting rubber strip commonly used category classification

- Half PU rubber strip

A: Structure: 2 floors

B: Standard thickness: 0.08mm 0.10mm 0.12mm

C: Standard color: matte light

D: Scope of application: suitable for a variety of waterproof fabrics, medium softness, good water resistance, especially for needle sewing with high waterproof requirements of clothing economy and practicality.

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 400-550 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

- Pure PU rubber strip

A: Structure: 2 floors

B: Standard thickness: 0.08mm 0.10mm 0.12mm 0.15mm

C: Standard color: matte transparent

D: Scope of application: suitable for soft waterproof fabrics, environmental protection, medium softness, good water resistance, also suitable for thin coating and uncoated fabrics.

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 350-600 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

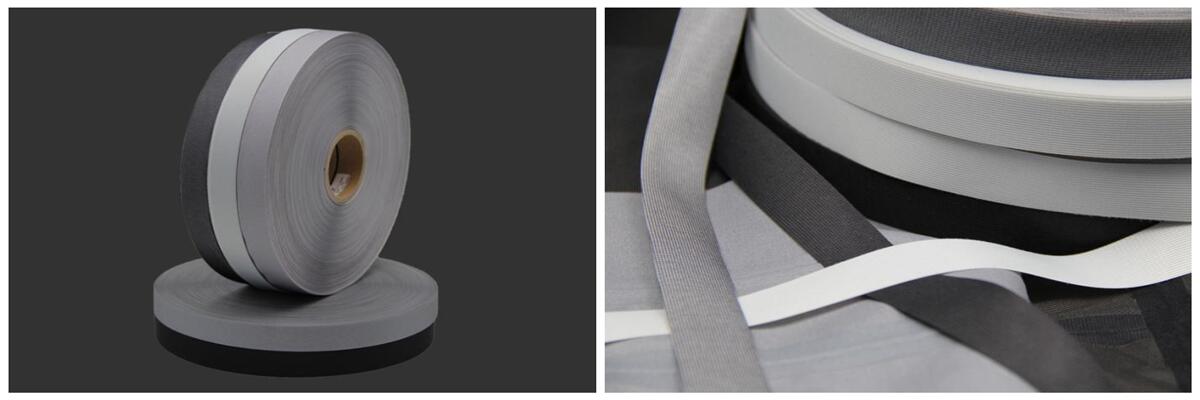

- Three layers with adhesive strip

A: Structure: 3 floors

B: Standard thickness: 0.30mm 0.35mm

C: Standard color: black, white and gray

D: Scope of application: suitable for three-layer waterproof fabric (elastic and inelastic), good water resistance, according to the different fabric with the corresponding rubber strip, can also be customized according to the fabric arrangement.

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 350-500 degrees

Pressure: 0.2-0.4 MPA

Time speed: 5-10M/MIN Temperature: 350-600 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

4, non-woven adhesive strip

A: Structure: 3 floors

B: Standard thickness: 0.12mm 0.16mm

C: Standard color: black, white and gray

D: Scope of application: suitable for sealing elastic three-layer waterproof fabric, good tensile elasticity, also suitable for PE rubber coating fabric.

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 350-550 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

5, 2.5-layer PU rubber strip

A: Structure: 2.5 floors

B: Standard thickness: 0.10mm 0.12mm

C: Standard color: various prints

D: Scope of application: printing adhesive strip, strong adhesion, various styles, can be customized characteristic pattern, decorative adhesive strip.

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 350-550 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

6, no sewing strong adhesive strip

A: Structure: 3 floors

B: Standard thickness: 0.30mm 0.35mm

C: Standard color: multiple colors

D: Scope of application: suitable for ultrasonic seamless paste cloth reinforcement (strengthening firmness).

E: Production conditions — the configuration parameters of the pressing machine are used when sewing clothes

Temperature: 400-550 degrees

Pressure: 0.1-0.2 MPA

Time speed: 5-15m /MIN

Second, the characteristics and production methods of waterproof rubber strip used in hunting clothes

At present, many hunting clothing fabrics have waterproof function, but the waterproof effect of the seam position is still poor. In the environment of heavy rainfall, water will penetrate through the clothing seam into the inside of the clothing, seriously affecting the waterproof of hunting clothing. The purpose of waterproof adhesive strip is to overcome the defects of the existing technology and provide a meet the application requirements, to achieve the waterproof effect of hunting clothing.

A: It can be achieved through the following technical solutions:

1, the use of multi-purpose waterproof adhesive strip matched with the hunting fabric, including the hunting body, and the waterproof adhesive strip heat-sealed in the sewing line position of the hunting body.

2, because the waterproof adhesive strip including from outside to inside compound TPU waterproof layer and PU hot melt adhesive layer, TPU waterproof layer thickness of 0.08mm-0.35mm, the hot melt adhesive layer thickness of 0.08mm-0.12mm, need to pass several tests to test, to meet the water pressure requirements.

- The waterproof adhesive strip is used to heat seal the suture line position of the garment body, which can significantly improve the waterproof effect at the suture line position. Due to the own characteristics of TPU waterproof layer and PU hot melt adhesive layer, it is not necessary to use glue to press the glue.

- Waterproof adhesive strip can be combined by hot pressing directly on hunting clothing fabric after softening by hot pressing, which avoids the traditional process of edge infiltration, poor adhesion and unequal adhesion phenomenon.

- Waterproof adhesive strip is thin and thin, which is mainly used for sewing inside the garment. No lining can be set on the inside of the garment after combination, and the garment integrity is better after combination.

- The waterproof tape feels smooth and smooth, which can avoid the discomfort caused by the bump and bump of the suture and improve the wearing comfort of the garment.

B: Specific implementation method:

- In the specific processing of adhesive strip, the thermal fan can be used to heat seal the adhesive strip under the conditions of the equipment operating temperature of 350 ~ 600℃, pressure of 0.06 ~ 0.15mpa and working speed of 3 ~ 6m/min. The waterproof adhesive strip can be heat-sealed on the seams of sleeve seam, shoulder seam, hem, side seam and other parts of the garment inside and side, so as to improve the waterproof effect of hunting suit.

- The body of the hunting suit can be made of nylon or PU fabrics and other outdoor clothing fabrics. The seam position includes the inside seam of the garment and the outside seam of the garment, and the inside seam of the garment is the main one.

- The method of attaching waterproof adhesive strip to hunting clothes solves the technical problems of difficult pressing, difficult operation and low efficiency of adhesive strip on different fabrics.

The method consists of the following steps:

Step A: the steps of attaching adhesive strips to the garment and placing them on the workbench of the arc press; Usually, the garment is first attached with adhesive strip to get the semi-finished product, and then the semi-finished product is placed on the arc table of the arc pressing machine. Of course, it can also be used to put the clothes on the work table of the arc pressing machine, and then the clothes on the work table are attached with rubber strips to get semi-finished products.

Step B: Control the pressing die head of the arc pressing machine to press on the adhesive strip attached to the garment obtained in Step A, so that the pressing die head is pressed at the set temperature of 130°C, pressure of 2.5kGF /cm2, and pressing time of 30 seconds. It is worth mentioning that the above temperature value, pressure value and pressing time value are set directly in the arc pressing machine, so that the arc pressing machine is suitable for the garment adhesive strip sticking process. In order to further improve the work efficiency, the arc pressing machine with two stations is selected. The steam function is usually not used in this process.

Step C: Remove the product from the bench of the arc press at the end of Step B.

Three, the advantages of waterproof rubber strip in environmental protection

Waterproof adhesive strip is a recyclable green evolution concept product, in the manufacturing and use of waterproof adhesive strip process almost zero loss, waterproof adhesive strip cutting the remaining edge material can be completely recycled and put into the material recycling process. Reduce energy consumption, reduce activation temperature, shorten shaping time, reduce carbon dioxide emissions, and reduce costs. It takes less time for the waterproof adhesive strip product to be fully activated, and the waterproof adhesive strip product only needs a lower temperature to be fully activated.

Waterproof adhesive strip products are 100% solid components, finished products or processing process completely solvent free, for the operator will not cause toxicity.

Waterproof adhesive strip products fully comply with the restricted substance specifications, and passed the SGS inspection, provide non-toxic certificate report.

In order to improve the quality of hunting clothing, TAIAN BOWINS Garment Co., Ltd. closely follow the development trend of hunting clothes, real-time improvement of technology, will serve customers with better products.